Although many people discuss how thru axles are stiffer than the quick-release skewer system that came before them, the primary reason current road and gravel bikes have adopted thru axles has more to do with the precise and repeatable positioning required by disc brake systems.

A Classic Design Over 90 Years Old

Quick-release skewers (as shown in the image above) have been with us for more than 90 years, and we’re all familiar with their design. Invented by Tullio Campagnolo as an improvement over wing nuts, they allow wheel removal without tools. They consist of a 5 mm diameter rod passing through a hollow axle, secured by a closing lever. The axle ends protrude beyond the axle nuts and sit in open dropouts on the frame/fork. The clever part is the cam mechanism inside the quick-release skewer, which quickly clamps the wheel to the frame.

Thru Axles: Stability from Closed Dropouts

Thru axles (as shown in the image above) use closed dropouts to secure the wheel to the frame/fork. Once the hub end caps fit into the slots in the frame/fork, tightening the thru axle clamps the system securely. There are mainly two types: one tightened with a hex key or Torx wrench, and another with a lever that threads the axle in before locking.

Thru Axles: Stability from Closed Dropouts

Thru axles (as shown in the image above) use closed dropouts to secure the wheel to the frame/fork. Once the hub end caps fit into the slots in the frame/fork, tightening the thru axle clamps the system securely. There are mainly two types: one tightened with a hex key or Torx wrench, and another with a lever that threads the axle in before locking.

Origins: Demands from the Mountain Bike World

Thru axles were first introduced in mountain biking to maintain rigidity in suspension forks and resist twisting and bending forces. Open dropouts struggled to handle the forces applied, especially on downhill mountain bikes. Riders wanted the fork legs to move only up and down, not twist side to side (except for steering input). The greater forces in mountain biking required larger-diameter thru axles to keep suspension forks intact.

Solving Disc Brake Alignment and Rub Issues

Thru axles also resolve many problems related to disc brake alignment and rotor rub. When not braking, the clearance between the disc rotor and brake pads is typically about 0.2–0.5 mm per side. In contrast, a well-set rim brake caliper with minimal wheel deflection allows 1–2 mm clearance per side. Disc brakes clearly have much tighter tolerances.

For the rotor, this is a very narrow passage to ensure the wheel spins freely. Rim brakes tolerate wheel misalignment better because the pad-to-rim clearance is larger.

Limitations of Quick-Release Skewers

With quick releases, the wheel doesn’t always return to exactly the same position each time it’s installed. On a bike with disc brakes, even a slight difference in wheel position can cause the pads to rub against the rotor.

A major advantage of thru axles is that the wheel returns to the identical position every time. It also makes it easier to confirm that everything is correctly reassembled.

How to Check Compatibility with Your Bike?

The hub must match the frame or fork in use. Hub width is measured from the outer faces of the locknuts (or between the end caps), known as O.L.D. (Over Locknut Dimension). Similarly, the frame/fork dropout spacing is measured from the inner surfaces of the dropouts (where they contact the hub’s locknuts or end caps).

For example, most rim-brake road bikes use quick-release axles: front 9 mm × 100 mm, rear 10 mm × 130 mm. In contrast, most modern thru-axle disc-brake road bikes use front 12 × 100 mm and rear 12 × 142 mm.

Thru Axles Are Part of the Frame

Quick-release skewers are generally interchangeable between bikes (depending on length) and are considered part of the wheelset. Thru axles, however, should be viewed as part of the frame or bike itself and are not easily swapped between bikes. While a 12 × 100 mm thru axle may seem identical on the surface, this only refers to the fork dropout spacing.

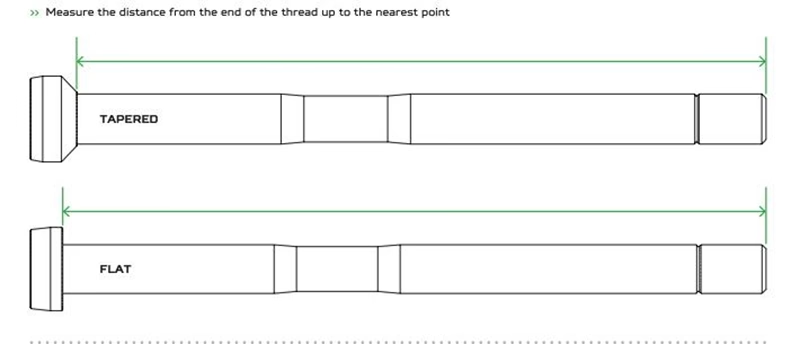

Thru axles themselves can vary in thread pitch (e.g., 1.0, 1.25, 1.5, or 1.75 mm), thread length (e.g., 16 mm or 18 mm), overall length, and head style (flat, tapered, or rounded). If any of these variables don’t match, issues can arise—or, in the worst case, the frame or fork could be damaged.

Coarser thread pitches (larger pitch) allow faster removal, while finer threads offer higher tensile strength, greater clamping force at a given torque, and better resistance to loosening from vibration.

Specifications and Torque

Thru axles usually have these specs etched on them, which is very helpful when replacing one. Looking at the KCNC axle example below, it’s easy to see it’s M12 × 142 (nominal diameter 12 mm, rear dropout spacing 142 mm), with overall length 161 mm (measured from under the head), thread length 18 mm, and pitch 1.5 mm.

The most user-friendly thru axles also conveniently mark the required torque on the outside of the head—typically in the 10–15 Nm range. If unsure, always check first. For example, Specialized recommends 15 Nm for both thru axles on their Aethos 2 bike. If the thru axle has a lever, torque can’t be measured directly, so a slightly different technique is needed.

Practical Tip: Use Anti-Seize Grease

One final thought on thru axles: when installing, it’s worth applying a thin layer of anti-seize grease to the threads and the axle shaft itself. This makes wheel removal easier and prevents corrosion between the bearings and axle.

Some manufacturers explicitly recommend this, while others don’t mention it. Always check your frame manufacturer’s guidelines first (note that adding grease may slightly change the torque needed to achieve proper clamping force).

Some Useful Information:

Common hub widths (O.L.D.):

Front wheel:

- 100 mm – modern front hubs, including quick-release and some thru-axle types

- 110 mm – some thru-axle front hubs, including 20 mm and Boost standards

- 135 mm – fat bikes

- 150 mm – fat bikes

Rear wheel:

- 120 mm – modern track bike hubs

- 126 mm – old 5-, 6-, and 7-speed road bikes

- 130 mm – non-disc road bikes, usually compatible with 8–10 speeds

- 135 mm – quick-release mountain bikes, most quick-release disc road bikes

- 141 mm – QR Boost

- 142 mm – thru-axle rear hubs

- 148 mm – Boost standard thru-axle rear hubs

- 150 mm – downhill bikes

- 157 mm – Super Boost standard thru-axle rear hubs

- 170/177/190 and 197 mm – fat bike rear hub sizes

Common quick-release and thru-axle sizes

Quick-release skewers are 5 mm in diameter, paired with 9 mm or 10 mm axle diameters. Length varies based on axle width (front/rear) plus dropout thickness.

Thru axles are typically 12 mm, 15 mm, or 20 mm in diameter. Length, thread pitch, and thread length are determined by frame requirements. They must match the frame exactly.