Threaded or Threadless? A T47 Bottom Bracket Technology Guide

Introduction to T47

The T47 bottom bracket standard has gained popularity for addressing an issue that arguably shouldn’t exist in the first place: the creaking noise from bottom brackets. T47 was initially developed by Chris King, with contributions from others. In essence, it is a threaded version of the PF30 standard. Due to the poor reputation of press-fit bottom brackets, some clever minds decided to brand it as “Threadfit T47.”

The root cause of bottom bracket creaking often stems from cost-cutting measures by bicycle manufacturers, who overlook critical geometric alignment features during frame production. This can result in eccentric bore diameters on either side of the frame. However, this explanation is not entirely accurate, as engineering tolerances are expected, but many manufacturers fail to meet even these basic standards. For context, the tolerances of injection-molded LEGO bricks are five times tighter than those of modern bicycles.

Many consumers lack the ability to inspect these issues or even realize they exist, and many bike shops don’t have the tools or equipment to check for these anomalies.

Virtually all bottom bracket types involve some form of press-fit. Bearings are either pressed into the bottom bracket shell or into the crank (as seen with Campagnolo systems).

Shimano designed their Hollowtech II system using the 6805 bearing, a common standard component with a load rating suitable for most cycling applications. This system is heavily patented, and to date, Shimano’s bottom bracket system is arguably the best. It uses a steel spindle, with consumable parts in the bottom bracket to prevent wear from insufficient crank rotation. The existence of 30mm and 29mm DUB/AXS bottom brackets is largely an attempt to circumvent Shimano’s patents.

The market often claims that larger-diameter spindles are stiffer, ignoring factors like material and bearing spacing. Nearly all 30mm and 29mm (SRAM) crank spindles are made of aluminum. These aluminum spindles make direct contact with hardened bearing inner races, and since aluminum is significantly softer than steel, this leads to spindle wear. The weight difference between a 24mm steel spindle and a 30mm aluminum spindle is only a few grams.

Choosing a 30mm aluminum spindle is not an optimal engineering decision, as the next standard bearing size after the 6805 is the 6806, which has a 30mm inner diameter.

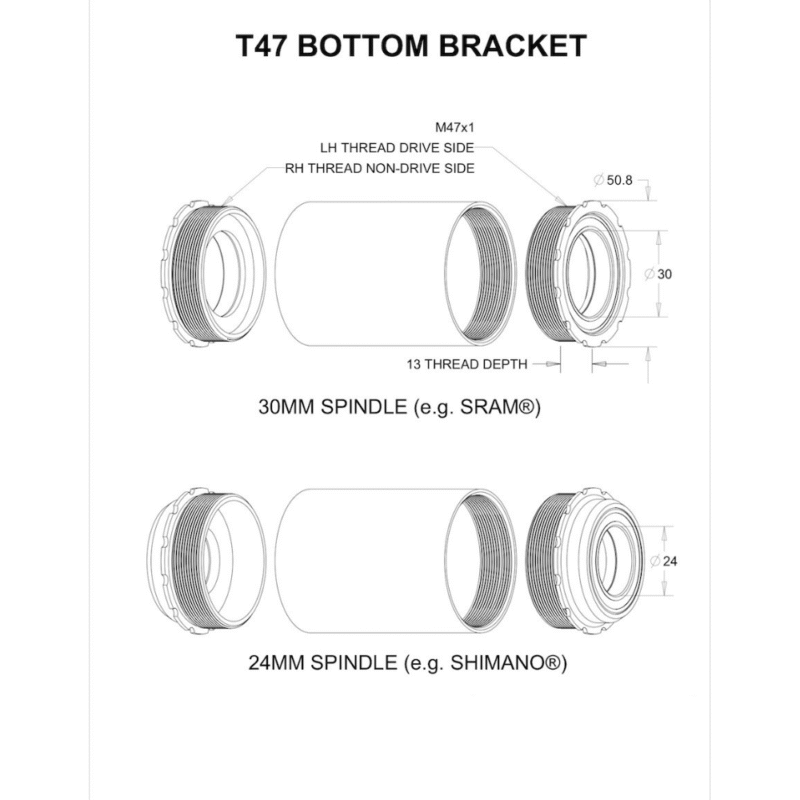

The BSA standard has long been the go-to for bottom brackets. Its shell geometry (1.375″ x 24TPI, approximately 35mm) is ideal for a 24mm spindle (with about 5.5mm wall thickness) but severely limits the use of a 30mm spindle (leaving only 2.5mm wall thickness). To accommodate this, the T47 standard was introduced, allowing for a 6mm wall thickness, nearly identical to the original 24mm/BSA combination.

However, the engineering design of T47 is not without compromises.

T47 Bottom Bracket Specifications

T47 comes in several variants, offering flexibility to manufacturers and consumers.

| Model | Thread (Internal) |

Thread (External) |

Width (mm) |

Notes |

|---|---|---|---|---|

|

T47-68 |

M47x1.0 |

M47x1.0 |

68 | Primarily found on custom metal frames. |

| T47-86 |

M47x1.0 |

M47x1.0 |

86 | |

| T47-85.5 |

M47x1.0 |

M47x1.0 |

85.5 | This standard is exclusive to Trek. In most cases, it is interchangeable with T47-86. |

| T47A-77 |

M47x1.0 |

M47x1.0 |

77.5 | This shell is asymmetrical, with the drive side being the same as T47-68 and the non-drive side being the same as T47-86. This is almost exclusively used for Felt and Factor bikes. |

Disadvantages

1. Weight

Weight is a primary concern for most cyclists. A typical T47 bottom bracket weighs approximately 180g. Additionally, the bike requires aluminum inserts or frame sleeves to match the T47 standard, adding roughly 100g. In total, this increases the weight by about 300g. For comparison, a BB86 bottom bracket weighs around 95g, and a PF30 weighs approximately 130g.

2. Tools

A specific variant of T47 includes a thin external flange (only 2mm thick) for tool installation and removal. However, this thin flange carries a high risk of thread slippage. Manufacturers like Trek, Felt, and Factor have indicated they will adopt this T47 variant. Thinner flanges eliminate concerns about crank clearance, making production simpler and more cost-effective.

Advantages

One undeniable advantage of threaded bottom bracket systems like T47 is their ease of use and installation, especially for the average consumer. With the right tools, T47 bottom brackets can be easily installed or removed at home without the need for specialized alignment or pressing tools. While frame tolerance issues may still cause misalignment, these can be mitigated with alignment sleeves.

For metal frames or relatively affordable frames, the T47 bottom bracket standard is an excellent choice.

Performance

The T47 Shimano system experiences slightly higher friction losses compared to the BSA Shimano system, primarily due to the bearings. T47 uses 6806 bearings, while BSA uses 6805 bearings. The difference is minimal but measurable. In terms of stiffness, the BSA Shimano system is more robust due to its smaller size and more precise absolute manufacturing tolerances.

However, press-fit bottom brackets like BB86 offer the best force transmission, as the load is transferred directly to the frame.