Bike Frame Custom Painting- Electroplating Coating Process

With the rise of bicycle culture, the surface treatment technology of frames has become a key link in improving the riding experience and vehicle value. Among them, electroplating coating process has gradually become a popular choice in the field of high-end bicycle manufacturing due to its excellent corrosion resistance, aesthetics and personalized customization potential. ICAN has demonstrated unique design aesthetics and practical performance through innovative electroplating coating technology. This article will deeply explore the principles and processes of electroplating coating process for bicycle frames, and combine the actual case of ICAN FL1 to help you fully understand this cutting-edge technology.

Principles and advantages of electroplating coating process

Electroplating coating is a process of depositing a protective or decorative metal coating on the metal surface through electrolysis. Common electroplating materials include chromium, nickel and copper, which can not only enhance the oxidation resistance and wear resistance of the frame, but also give the frame gloss and personalized color. Compared with traditional spray painting, electroplating coating has stronger adhesion and uniformity, and can achieve seamless coverage on frames with complex geometric shapes. In addition, the electroplating layer can effectively resist the erosion of the external environment (such as rain and salt spray) and extend the service life of the frame, which is particularly important for cycling enthusiasts who pursue high performance.

ICAN Customized Coating Process

The electroplating coating process of the carbon slim bicycle frame demonstrates the exquisite technology from raw materials to finished products. The process is roughly divided into the following steps:

1. Surface pretreatment: Remove oil and defects on the surface of the frame through chemical cleaning and mechanical polishing to ensure the cleanliness of the coating base.

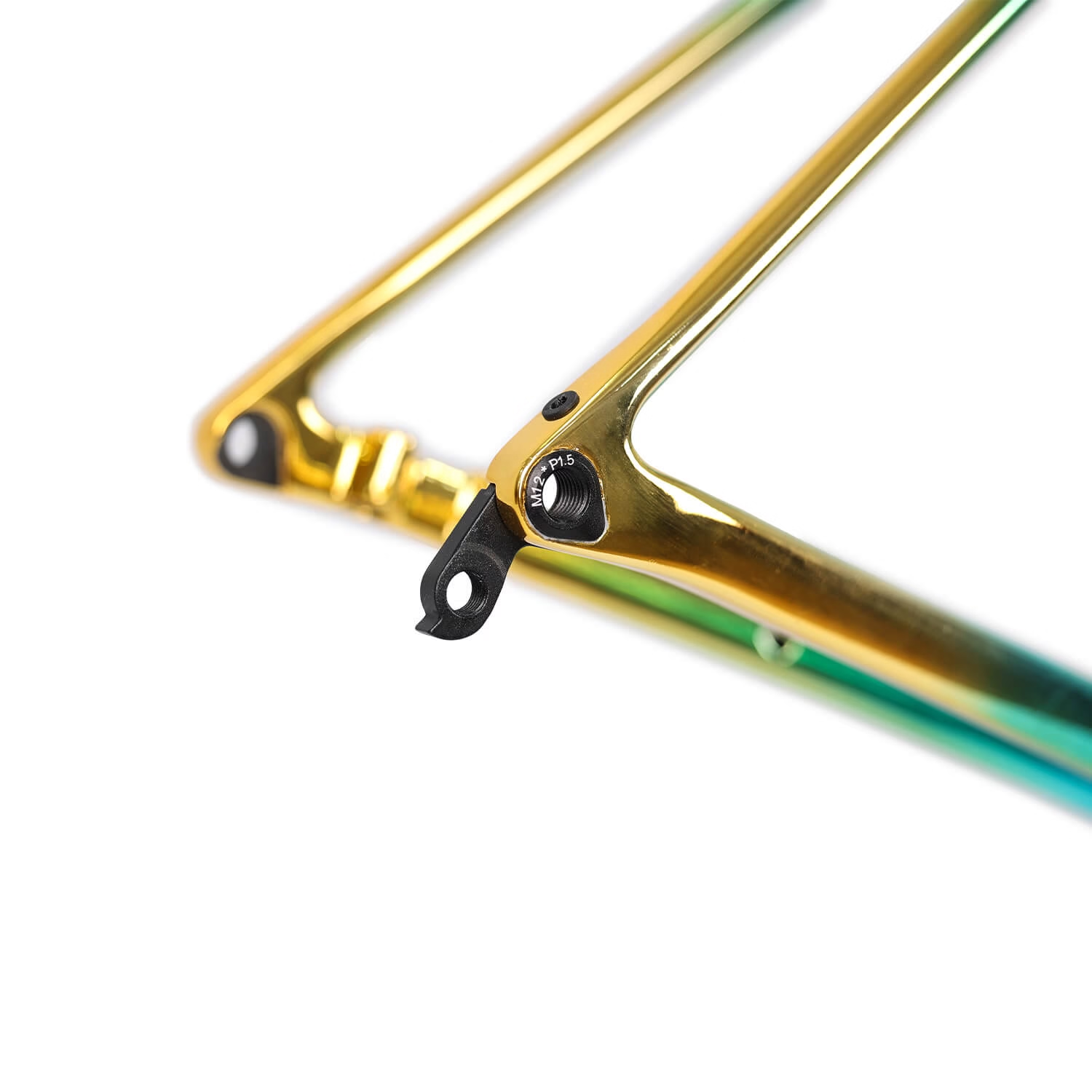

2. Electroplating layer deposition: Place the frame in the electrolytic cell and gradually deposit the metal layer by controlling the current and electrolyte composition. The ICAN FL1 frame case uses gradient electroplating technology. As shown in the figure, its frame gradually transitions from gold at the top to blue at the bottom, presenting a smooth and dazzling visual effect. This gradient design is achieved through precise electroplating parameters.

3. Post-processing and sealing: After electroplating, the frame is cleaned, dried, and coated with a protective layer to further improve weather resistance and glossiness, ensuring that the color lasts.

4. Customized adjustment: According to customer needs, personalized designs such as color gradient and pattern inlay can be supported. The gradient gold and blue color shown in the picture is an outstanding example of customized services, which meets the unique aesthetics of different riders.

Application of electroplating coating

ICAN FL1’s electroplating coating performs well in practical applications. The gradient color frame shown in the picture is not only visually eye-catching, but also presents different color changes according to the angle of light, which is deeply favored by professional riders and collectors. In addition, the durability of the electroplating layer has been rigorously tested and can remain stable under various climatic conditions, which is particularly suitable for long-distance riding or off-road scenes. Market feedback shows that ICANBikes’ customized coating service has significantly improved the recognition of personalized high-quality pursuers, and many users say that its unique appearance has become the best carrier for showing personality.

Icanbikes’ personalized customized coating service

As a leader in the carbon fiber bicycle industry, Icanbikes is committed to providing every rider with an excellent customized experience. Whether it’s the color combination of electroplating, such as the gold and blue gradient design of ICAN FL1 in the picture, or the addition of unique patterns, we can tailor a frame to your needs. Choosing Icanbikes not only gets you high-quality carbon fiber bicycle frames, but also enjoys personalized customization services provided by a professional team, opening a new chapter of your riding.

Build your dream ride! Contact us now to explore more customization possibilities!